What are Extruded Aluminum Enclosure Profiles?

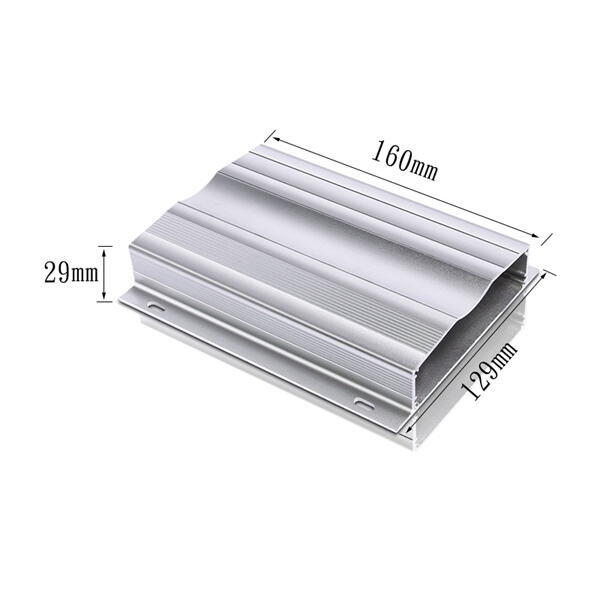

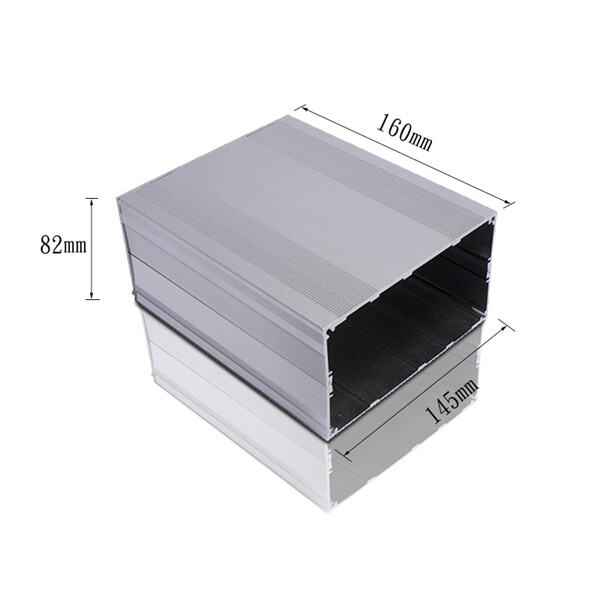

Extruded Aluminum enclosure profiles are types of Aluminum enclosures that have been shaped into a specific form for a specific use, also the Hongfa Shunda's product such as abs plastic enclosure. They are created by extruding the Aluminum through a die, which gives it its shape.

Extruded Aluminum enclosure profiles come with several advantages, similar to the plastic enclosure box for pcb by Hongfa Shunda. Firstly, they are lightweight and durable, making them perfect for use in electronic enclosures. They do not rust or corrode easily, making them long-lasting and low maintenance. They can withstand harsh weather conditions and extreme temperatures, making them versatile and reliable. They also have a high resistance to impact and vandalism, making them a good choice for public spaces.

There has been a lot of innovation in extruded Aluminum enclosure profiles, as well as the Hongfa Shunda's extruded aluminum enclosure profiles. New designs are continually emerging with improved features. Innovative features include better thermal management, more precise machining, better sealing, and customized designs. These innovative features have made extruded Aluminum enclosure profiles even more useful for a wide range of industries.

Safety is always a top priority when it comes to any product, just like the plastic enclosure diy manufactured by Hongfa Shunda. Extruded Aluminum enclosure profiles are no exception. They are designed to be safe to use in various industries, including critical electronic applications and commercial settings. They have been tested and certified to meet industry standards and regulations to ensure that they are safe for their intended use.

Extruded Aluminum enclosure profiles have several uses, along with Hongfa Shunda's product abs electronic enclosures. They are commonly used in the electronics industry, where they provide a protective casing for electronic devices and components. They are also used in the automotive industry, where they are used to create sleek designs for car exteriors and interiors. The aerospace industry also utilizes extruded Aluminum enclosure profiles for their lightweight and strength properties. They can also be used for outdoor lighting fixtures, industrial enclosures, and more.

Full product ranges, plastic boxes, aluminium enclosures sheet metal housings. We offer CNC precision machined components, standard products custom-designed OEM products meet various requirements various customers. Our plastic metal cases used variety industries and applications include electronics, construction medical equipment, many more. We have solutions meet your needs, whether you want durable, small case USB large rugged case power tool.

Hongfa Shunda put quality first every extruded aluminum enclosure profiles, starting conception product, acquisition raw materials, monitoring process along 100% appearance inspection before shipment packaging, making highest effort make sure item purchased client reputable high quality.

We provide customized solutions satisfy customers' individual extruded aluminum enclosure profiles. comes prototyping, machining, assembly, work close collaboration clients create solutions exceed expectations. From CNC laser cutting machining, sheet metal fabrication welding provide broad range manufacturing capabilities accommodate variety industries applications. manage complex projects beginning finalization, using full range service.

manufacturing facilities extruded aluminum enclosure profiles cutting-edge technology modern machinery, enabling produce high-quality precision parts unparalleled accuracy efficiency. team comprised highly competent engineers, technicians, artisans have wealth experience knowledge metalworking. pay close attention every aspect ensure each item highest standard quality precision standards.

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. All Rights Reserved - Privacy Policy