How to Make Your Own Plastic Enclosure at Home

Do you want to show off your electronic projects? One of the easiest ways to do by creating your plastic enclosures at home, identical to Hongfa Shunda's product plastic enclosure box. If you have the correct materials, tools, and instructions it is not that difficult to do. You can also create your own enclosure - Dedicated to only house you projects.

The Importance of Choosing the Right Materials The choice of materials for a plastic enclosure is extremely important. You can use polycarbonate, acrylic or abs material as they are light in weight and strong materials but not that cost-effective. You will also need the right tools such as a ruler, scriber, drill press (if possible), heat gun and jigsaw. And now you are ready to create your custom enclosure with these tools and material.

Fund Projects That Are Fun For Your Electronics

Building your own plastic enclosure means you can go wild when it comes to displaying whatever projects of yours that would otherwise be obstructed by industrial metal. Enclosures for amplifiers, gaming consoles or speakers. Cool idea, Box with see through lid Advanced setups like LED light strips could also be placed in a special enclosure.

Reasons Why You Should Build Your Own Enclosures

Making your plastic enclosures comes with many advantages, along with the black plastic enclosure from Hongfa Shunda. For once, it is a money saver in the sense that you are making them yourself. Secondly, you could include a special touch to your current projects. Lastly, your do-it-yourself enclosures will be more sturdy and lengthy lasting compared to the made ones that you may buy. And also you can verify the form factor of enclosure fits perfect for your project, So don't have to worry about fixing it.

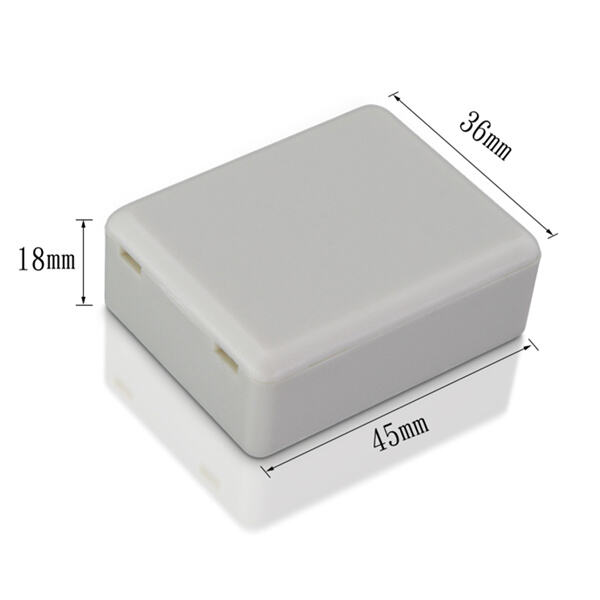

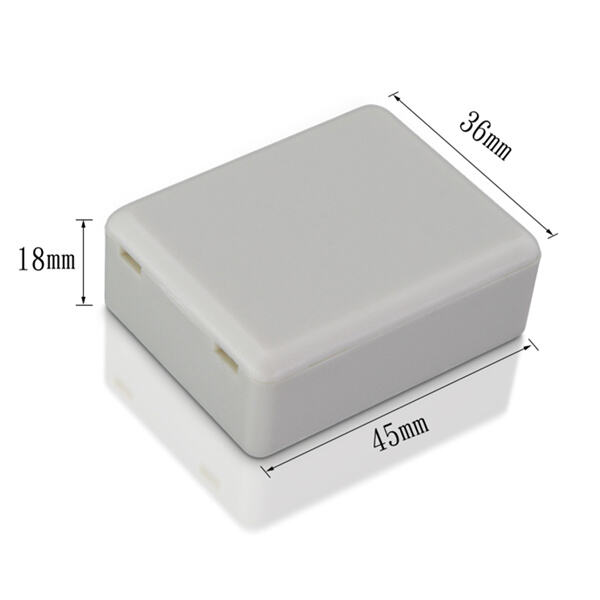

The guidelines for designing a plastic enclosure are well defined and often quoted details of good design practices, identical to Hongfa Shunda's product abs project boxes. Add textures or colors to make your enclosure even cooler. Ensure that it is the right size for all your project parts. Ventilation is also an importance in the enclosure. Oh yea, and plan, in detail before you build anything.

It is an easy and satisfying experience to build your own plastic enclosure, as well as the electronic enclosure box supplied by Hongfa Shunda. You will have a cool and unique way to present your electronics projects. By using the helpful tools, materials and tips provided here on this article you will be able to create your own long lasting plastic enclosure.

Find Out Just How Much Fun it is to Make Your Own Plastic Case at home through the Art of Crafting

Are you in electronics hobby grades or a maker wanting to present your projects differently? The ideal solution for you could be making your own plastic enclosures at home. Well, with the right tools and materials it is not as hard or scary as it might seem we promise. Explore the role of DIY enclosures to make a customised casing for your projects that expresses who you are and does what you need it to.

Tools and Materials You Need For Your Project

Choosing the Correct Materials for a Plastic Enclosure Project Go for the lighter weight, stronger and cheaper options like polycarbonate acrylic abs. Its tools include a ruler, scriber, drill press heat gun and jigsaw along with others. And with these tools and materials, you are set to get started building your very own personalized enclosure.

Cool Ideas in Electronic devices Do-it-yourselfassignments

Learn how to Create Custom Plastic Enclosures For Your Electronic Projects

Build an Byte-sized Unleash Channel snippit The possibilities are endless, be it an amplifier or gaming console, maybe a speaker Try designing a hinged box with an open top, or maybe even a clear lid for viewing the gears of your creation-component. Or instead, dive into the cutting-edge of technology concerning brewing and make housings for things like LED light strips etc.

Abundance of Pros - Why DIY Enclosures Triumph

There are lots of reasons you might want to make plastic enclosures on your own. To begin with, this is a less expensive project that can save you money on the purchase of pre-fab enclosures. It brings your projects. up a notch by allowing you to add personality and visual style / flavour; Lastly, in general custom-built enclosures are much more stronger and durable than their store-bought counterparts. In addition to this you can make sure the enclosure is sized for your application, giving it top level protection.

How to Best Enclose Your Property With the Assistance of An Expert

Using a good plastic enclosure, relies with great care to detail on your part. For a superior quality of style to enhance your creation, you can insert textures or colors inside the button. Make sure that the dimensions of your enclosure provide enough room for all parts to fit comfortably. Minimum of ventilation during construction process. Have your complete schematic and blueprint of the enclosure before you begin anything so that having to backtrack changes will be as minimal or non-existent.

Hongfa Shunda places product quality first. starts design, purchase Plastic enclosure diymaterials, observing step process, 100% inspection appearance prior shipment packaging.

We provide customized solutions satisfy customers' individual Plastic enclosure diy. comes prototyping, machining, assembly, work close collaboration clients create solutions exceed expectations. From CNC laser cutting machining, sheet metal fabrication welding provide broad range manufacturing capabilities accommodate variety industries applications. manage complex projects beginning finalization, using full range service.

complete product line, ranging starting plastic boxes, aluminium enclosures sheet metal housings. offer CNC precision machined components, standard products OEM custom products, meet different needs different customers. Metal plastic cases utilized various industries applications, including construction, electronic equipment medical equipment, . matter need tiny robust case protect USB larger, rugged case protect power tools, have solution.

manufacturing facilities Plastic enclosure diy cutting-edge technology advanced machinery, enabling make high-quality precision components unmatched precision efficiency. team consists highly experienced engineers, technicians craftsmen who possess years experience expertise metalworking. pay close attention every single detail ensure product exceeds highest quality precise standards.

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. All Rights Reserved - Privacy Policy