How to Look Out For the World of CNC Machining Precision Parts

Have you ever wondered how all the parts in airplanes, cars or toys are made? If the answer is yes, then you are in for quite an exciting ride as we explore CNC machined precision parts.

CNC machining is an incredible process that allows for small, accurate parts to be manufactured with record low tolerances. Where people used manual tools like hammer and chisels to create parts in the past, today Computer Numerical Controlled machines (CNC) are star that keeps producing one component after another. Such a high level of precision is vital, particularly in domains like medical devices and aerospace where accuracy becomes everything so opt for

cnc precision parts from Hongfa Shunda.

CNC machining is incredibly versatile—it can be used to create tiny, cut planes from an aircraft wing or they even precision drilled holes in jet engines for aerospace tools. It's also one of the longest-lasting forms of manufacturing capable and strong enough to undertake complex projects involving difficult materials like titanium. The Cnc Machining Parts from Hongfa Shunda are able to produce parts otherwise impossible for, say, an unskilled worker cutting and shaping them with basic tools by the mere nature of using advanced cutting/shaping equipment based on detailed plans.

CNC machining has a lot of benefits. It is so fast, it can create huge numbers of parts in short order. This ability to produce at unnecessarily fast speeds embodies the true advantages of three-dimensional printing, generating parts in less than an hour for industries like automotive and toy manufacturing that depend on a seamless supply chain. In addition to this level of detail, turning cnc machining parts from Hongfa Shunda is also very accurate meaning every part will have precise measurements; a concern in industries like healthcare as well aviation.

The prime advantage CNC machining is that custom parts are able to be tailored based upon the intended purpose for which such component requires. CNC machining can give parts the specific measurements required for their use; this might mean ensuring that an has exactly 15 threads per inch or making certain that an engine part is measured to fit perfectly within existing schematics. This level of customization makes operations within companies much easier, ensuring that every part fits exactly as intended in to the overall design and flow so for precision cnc parts.

CNC Machining has revolutionized the manufacturing process It been a game changer for industries such as automotive and aviation with parts being able too be produced more quickly, cheaper and accurate than ever before. It has opened a door for making really complex items, which we once thought impossible too make by hands. Now, the next time you are playing with a toy or catching a flight in an airplane, pause for a second and admire all these things that have been possible only because of cnc precision machining parts!

Hongfa Cnc machining precision parts always put quality first every spot, from creation product purchase raw materials, monitoring each process 100% appearance inspection before shipment packaging, with highest level effort ensure every item purchased customer qualified high quality.

team consists highly-trained technicians, Cnc machining precision parts craftsmen years knowledge experience metalworking. meticulous attention detail, ensure every component meets strictest requirements quality precision.

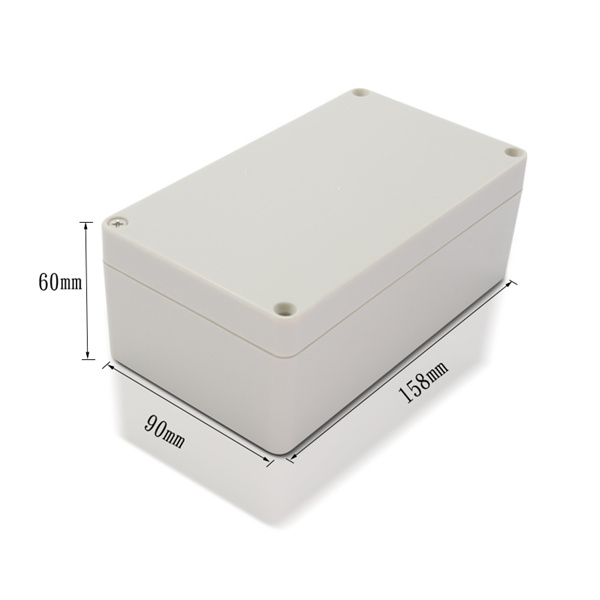

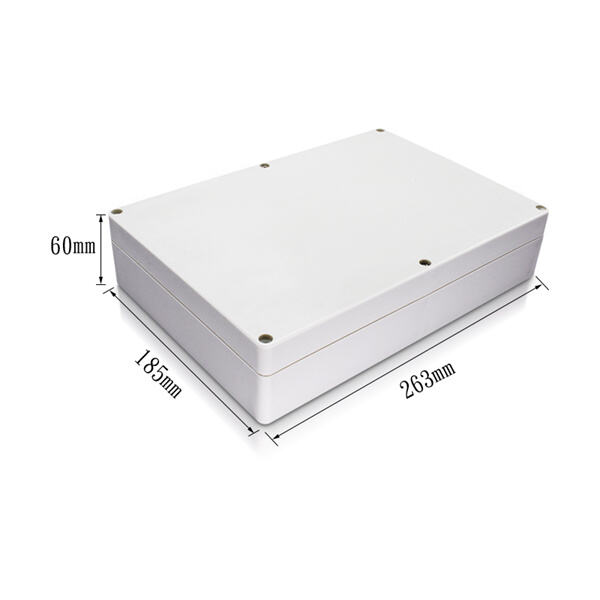

Full product ranges, plastic boxes, aluminium enclosures sheet metal housings. We offer CNC precision machined components, standard products custom-designed OEM products meet various requirements various customers. Our plastic metal cases used variety industries and applications include electronics, construction medical equipment, many more. We have solutions meet your needs, whether you want durable, small case USB large rugged case power tool.

We realize every project unique, create custom solutions designed meet specific needs clients. We Cnc machining precision parts clients develop solutions meet expectations, matter making prototypes machining. handle most complex tasks, design completion, complete service.

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. All Rights Reserved - Privacy Policy