STAINLESS STEEL CNC MACHINING COMPONENTS - A SURPRISING WORLD

Stainless steel CNC machining pieces are some of the most impressive innovations hailed as cutting-edge by technology. These Hongfa Shunda vattentät elbox characteristics manufactured with the help of advanced machines that are computer programmed offering exact and complex metal parts. If you are an existing expert in the process of stainless steel CNC machining and if you wish to state that fact through this content or beginner just starting off with your learning, we advise that it would be best for 1st time sure know deeply about the intriguing field.

The journey for producing high-precision stainless steel cnc parts starts with the creation of specialized computer software which works as a blueprint and source program for this machine. This software tells the Hongfa Shunda kopplingsdosa utomhus what specific actions to take in order that it can turn raw metal into a specific component. Using a variety of tools such as spinning blades, lasers and cutting implements the machine mechanically shapes the metal in what is called "machining". The final stage ends with a comprehensive check of the mechanical condition of the last produced part.

This is when stainless steel comes into picture as the perfect type of material for making precision machined components that are longer lasting and reliable. The first type of metal became rust-free for a very long time as it was noted to be highly resistant to corrosion almost never seen in any other kind of metals. Moreover, the sanitary properties of stainless steel are second to none and it is an easy choice in sectors such as medicine or food processing. The Hongfa Shunda vattentät kopplingsdosa and corrosion resistance of stainless steel machined parts make them ideal picks to be used for an array of applications.

There are many benefits of stainless steel which confide the customer to use this metal for your Machined product. vattentät elbox utomhus not only assures precision and accuracy thereby reducing the human error on production level, but gives an economical solution for many intricate parts of complex geometries that are tough or cost heavily to manufacture otherwise. Such parts are very impractical to be produced by the other methods of manufacturing but this machining process makes them relatively easy.

facilities manufacturing stainless steel cnc machining parts cutting-edge technology modern machinery allows make high-quality precision parts unparalleled accuracy efficiency. Our team comprised highly knowledgeable engineers, technicians craftsmen have years expertise experience metalworking. eye each detail, make sure every component meets strictest requirements quality accuracy.

Hongfa Shunda put quality first every stainless steel cnc machining parts, starting conception product, acquisition raw materials, monitoring process along 100% appearance inspection before shipment packaging, making highest effort make sure item purchased client reputable high quality.

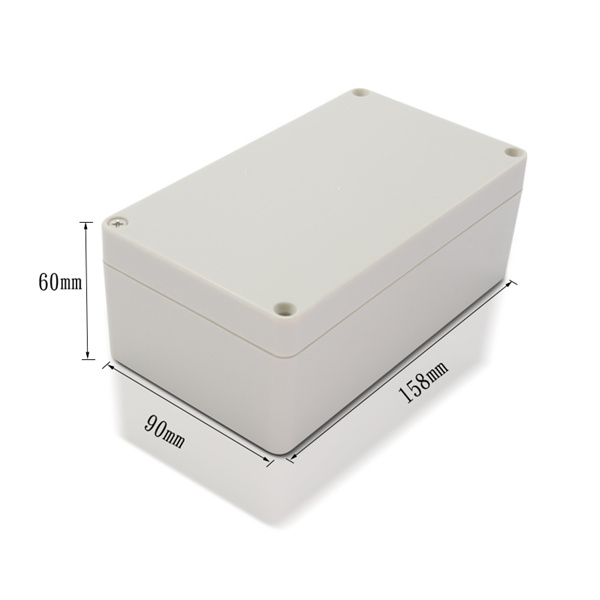

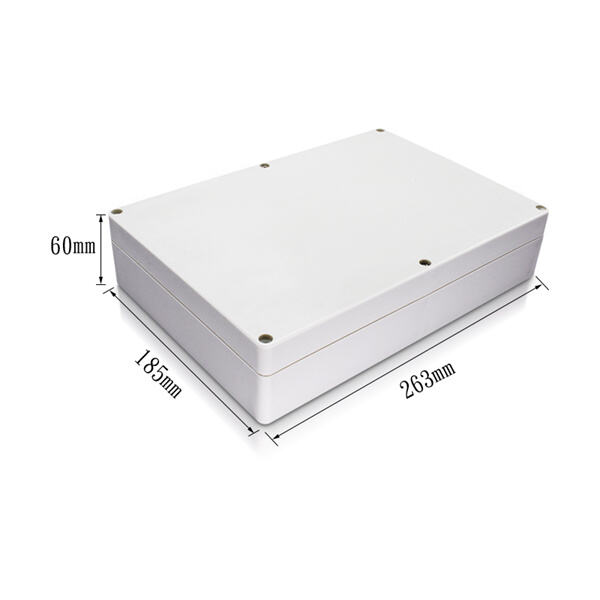

möta krav kunder, vi har omfattande produktlinjer som omfattar aluminium, plast och plast kapslingar, plåt höljen. även CNC precisionsbearbetade komponenter standardartiklar OEM-artiklar, andra produkter. Plast metallfodral lämpliga industriapplikationer inklusive konstruktion, elektronisk utrustning medicinsk utrustning, mer. Vi har lösningar för dina behov, oavsett om det är starkt, litet USB-fodral, stort robust fodral elverktyg.

We realize every project unique, which provide stainless steel cnc machining parts solutions tailored meet particular requirements customers. Whether prototyping, manufacturing, assembly, collaborate clients deliver solutions exceed expectations. From CNC laser cutting machining, sheet metal fabrication welding We offer broad range manufacturing capabilities accommodate variety industries applications. broad range services allow manage large-scale designs idea final.

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. Alla rättigheter reserverade - Integritetspolicy