Metalen onderdelen die in grote hoeveelheden in de industrie en het dagelijks leven worden gebruikt, kunnen worden vervaardigd met een permanent-motiefpatroon in een proces dat bekend staat als aluminium drukgieten. Het is cruciaal om te weten dat dit proces begint door aluminium te smelten tot het ongeveer zo vloeibaar is als water. Dit gesmolten aluminium wordt vervolgens in een op maat gemaakt vorm, bekend als een vorm, gedrukt. De vorm bestaat uit twee stalen stukken die perfect bij elkaar passen om de omtrek van het onderdeel te vormen.

Hoe gebeurt het proces?

Vormen van de stoot: De eerste stap in het aluminium gietsproces bestaat uit het maken van de stoot. Ze pakken twee stukken staal en vormen ze op precies de juiste hoeken. Ze zorgen ervoor dat, nadat het aluminium is gesmolten en in de vorm gegoten, het alle details vult en het gewenste onderdeel creëert. Dit is erg belangrijk omdat de uiterlijke verschijning van het eindproduct afhankelijk is van de vorm.

SMELTEN VAN HET ALUMINIUM – Daarna wordt het aluminium verhit. Arbeiders gooien het aluminium in een haard. De temperatuur smelt het aluminium volledig. Het wordt dan overgebracht naar een andere oven nadat het gesmolten is. Dit zorgt ervoor dat het aluminium warm blijft en klaar is om gebruikt te worden.

Vullen van het aluminium: Zodra het aluminium is voorbereid, is de volgende stap om het aluminium in de vorm te gieten. Het vloeibare aluminium wordt onder hoge druk in de vorm gepompt. Deze druk is extreem belangrijk omdat het ervoor zorgt dat het aluminium elke hoek en nis van de vorm vult. Wanneer het aluminium de vorm volledig heeft gevuld, neemt het de exacte gevraagde vorm aan, zodat het eindstuk zeer gedetailleerd en nauwkeurig is.

Afkoeling, Onmiddellijk nadat het aluminium de holte van de vorm binnenkomt, koelt het af. Het vloeibare aluminium koelt dus af om vast te worden. Wanneer het gesteld is, is het uitermate sterk en bruikbaar.

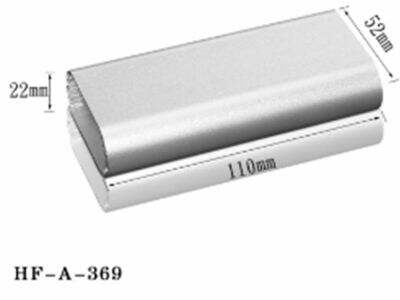

Nadat het aluminium is vastgekoeld, de extrudeerde aluminium behuizingen vorm opent zich, waardoor het deel wordt verwijderd. Dit is het moment waarop het nieuwe deel wordt verwijderd. Soms zijn er ook overtollige delen die niet meewerken - werknemers knippen deze dan af. Ze poetsen ook het deel om er voor te zorgen dat het esthetisch aantrekkelijk is en klaar voor gebruik.

Belang van aluminium drukgieten

Aluminium drukgieting speelt een belangrijke rol in de productie van een breed scala aan producten. Deze procedure stelt producenten in staat robuuste maar toch lichte onderdelen te produceren. Machines die hiervoor gebruikt worden aluminium gietkast worden op zeer nauwkeurige wijze toegepast. Ze produceren elk individueel onderdeel zo nauwkeurig, dat de onderdelen uiteindelijk goed passen en correct functioneren. Dit maakt het mogelijk om deze onderdelen te gebruiken in verschillende toepassingen, van voertuigen tot luchtvaart tot elektronica.

Waar We Drukgecaste Onderdelen Toepassen

Er zijn verschillende industrieën afhankelijk van aluminium drukgieting. Neem bijvoorbeeld aluminium drukgieting in de automobielsector; met aluminium drukgieting kunnen belangrijke autocomponenten zoals motorblokken (het hoofddeel van een auto-motor) worden vervaardigd. Een dergelijke toepassing in de luchtvaartindustrie is het vervaardigen van kritieke onderdelen voor vliegtuigen die helpen bij veilig vliegen. Aluminium drukgieting wordt gebruikt in de elektronica-industrie om behuizingen en hulzen te produceren die computers en smartphones beschermen.

Tenslotte, Hongfa Shunda is Plaatmetalen behuizing fabrikant die de kunst van precisiebewerking heeft beheerst en hoogwaardige producten tegen concurrerende prijzen aanbiedt. We zijn trots op de kwaliteit van onze onderdelen, en we zorgen ervoor dat onze onderdelen niet alleen geschikt zijn voor onze klanten, maar ook dat onze klanten tevreden zijn met onze onderdelen. Om te ontdekken hoe onze drukgietdiensten uw sector en uw behoefte aan de beste onderdelen kunnen dienen, neem direct contact met ons op. Aarzel niet om uitkomstig naar vragen te komen; we staan graag meer details te delen.