Injection molding (basically) is where liquid plastic is forced into a mold (to make shapes). A mold is an empty space where the plastic material can flow through to get its shape. Once the mold is in place. The molten plastic is left to cool. Plastic becomes hard enough to be shaped like a die after cooling. We can make simple plastic toys for kids and complex surgical instruments for doctors.

Plastic Materials Used:

Injection Molding Plastics Plastics come in many shapes, sizes, composition and properties. Each type of plastic has its own features and benefits. Here are a few:

Polyethylene (PE) is one of the most widely used plastics and is used in an array of applications. You see it in plastic bags and milk jugs. Vulcanized rubber is moldable, supportive of weight, and impervious to most chemicals that destroy other materials.

Polystyrene (PS): A low weight, very rigid type of plastic. Typically used for packaging such as boxes or containers and products for single-use. You can shape it in great breadth, and it is also clear meaning: you can be perceived through it.

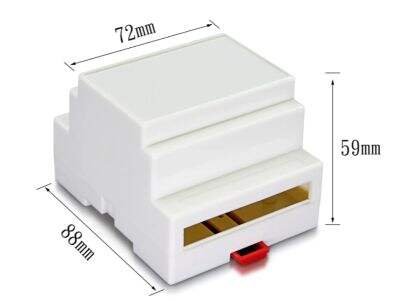

ABS (Acrylonitrile butadiene styrene): This abs plastic injection housing is a tough and strong plastic that is also used in many automotive applications in other words, found in a car. It is resistant to impacts which means that it will not break if it gets a hit so it can handle heat well. It also has excellent mechanical features making it ideal and valuable in many applications.

Polypropylene (PP): Another versatile, all-purpose plastic used in everything from everyday items to medical tools. Light in weight, it is easy to carry and resistant to a large number of chemicals which means it will not get damaged easily. It is also highly customizable to different shapes.

How to Select the Appropriate Plastic for Injection Molding?

Several important factors need attention when choosing an injection molding plastic꞉

The plastic needs to be strong. It must handle the job it is meant for. For example, a toy that kids play with needs to be very sturdy. It has to survive rough handling without cracking.

Chemical Resistance: Where a product comes into contact with chemicals as is the case of cleaning supplies or containers for food, for example, it is crucial for the plastic not to be damaged or destroyed by that chemical action

Temperature resistance: Some plastic outdoor enclosure products can use high-temperature conditions or low-temperature regions. So, the plastic will have to withstand those temperatures without damage or deformation.

Look: The plastic does not just need to be functional, but it might need to look a certain way too depending on the gm. Perhaps, the product will need to be translucent, so you can see what is inside, while other components may have to be colored for some design.

Other Factors to Think About

While selecting a plastic, we also have to consider:

Cost: The cost of money for some types of plastics differ. A few are slippery, while a lot could be very high-priced. While working with plastic and deciding, it should be kept in mind how much the plastic will cost.

Production Requirements: Some of the plastics require special kinds of machinery or methods in order to form them rightly. This can make the entire process complicated and expensive.

Environmental Impact: Also, how that plastic injection housing impacts the environment must be taken into account. Not all plastics are created equal. While some plastics do worse in nature than others.

Pros and Cons of Various Types of Plastics

There are different kinds of plastics for injection molding with unique benefits and limits. Remember these important points꞉

Polyethylene (PE)꞉ PE is cheap, shapes easily and resists chemicals well.

CEC-M4 (another type)꞉ It has strong dielectric strength but struggles with high heat and has lower strength than other plastics.

Polystyrene (PS)꞉ This plastic is clear and affordable. It handles impacts fairly well. But it does not resist moisture well and has trouble in very cold weather. These limits restrict its uses.

Acrylonitrile Butadiene Styrene (ABS)꞉ ABS has many benefits like high strength and good heat resistance. It also finishes nicely. Its cost can be higher than other options and it fades under UV rays.

Polypropylene (PP)꞉ PP is cheap and resists chemicals well. It also stands up to fatigue.