All About Plastic Enclosures!

Custom Designed containers to adept as a container that is designed with the use of plastic and helps in several applications called, Plastic Enclosures. They are also lighter as well impenetrable to any other kind of corrosion, in contrast with metal or wood containers. They are also cheaper, and easier to adapt for different sizes.

Plastic Enclosures Advantages

Here are some of the reasons why plastic enclosures continue to be a choice for many industries; Quite lightweight but crazy tough... perfect balance between toughness and easy handling Plastic enclosures are corrosion or rust-proof (though not all types offer these characteristics), so they live longer as well over a period. Plus, they are more cost effective than the metal or wooden conduits that you currently have. They can also be easily machined and thermally formed into a wide range of shapes and sizes for any number of enclosures, tailored to the requirements with careful design.

New Revolution in Plastic Housings

That battle, combined with repeated technological advancements has done wonders and plastic enclosures have developed significant resistance against the odds in years gone by. For instance, some cases now feature UV light stabilizers that protect from the destructive effects of sunlight and help them last longer. Furthermore, their anti-static additives are such that they prevent static discharge which allows them to be used near sensitive equipment. As a result, plastic enclosures are now being deployed in an increasing number of new roles for which improved dependability is essential.

Safety Considerations

Safety and ComplianceThe next thing you need to be aware of about plastic enclosures is the safety aspect, wherever its use in applications stringent rules are put down by various regulatory bodies qualifying which kind will pass them. You have to provide "absolutory" assurance that the case obeys all safety regulations, especially with regard to it being suitable for both voltage (or current) ranges as they will be enclosed. It is extremely important to test them for shock and fire resistance, so that they do not be a cause of any hazards. Also, the materials used for creation of the enclosure must not be toxic or have any adverse effects on human and it electromaterials should no releases destructive substances to environment.

How to Use Plastic Enclosures

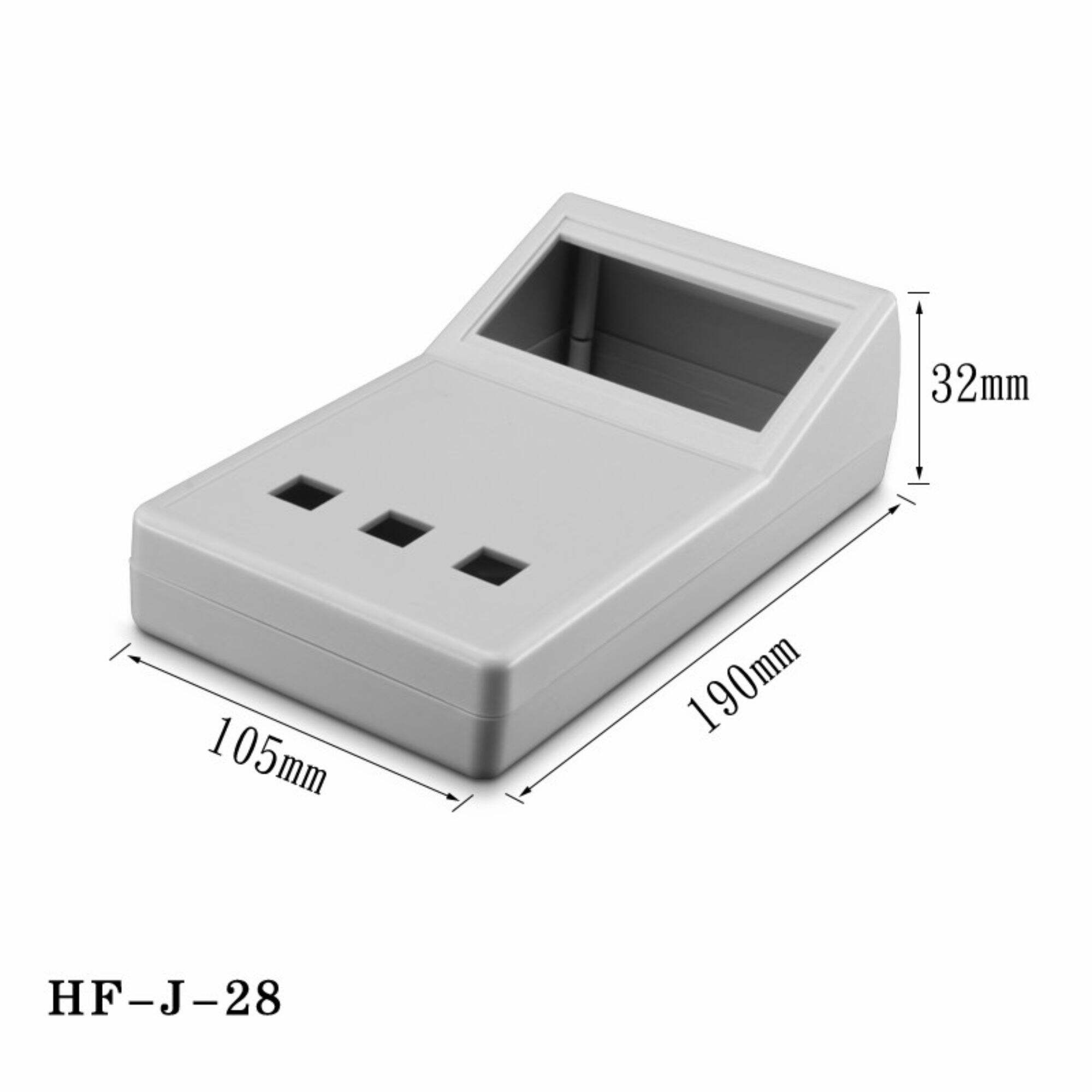

The first step to using a plastic enclosure is finding the right size and shape style for your needs. It is quite essential to buy the right enclosure from an authentic place as it will offer assurance for quality and standards incorporated in one. Upon receipt of the enclosure, it is mandatory to perform a thorough inspection for damages or defects prior to proceeding with installation. Properly wiring up all other correct wires and components in tandem while also making sure that it works as intended, while keeping the enclosure safe.

Choosing a Good Supplier

The market for your plastic enclosures is determined to a large extent by the quality of suppliers who will give you reliable service in addition to satisfying high-quality products. Choose suppliers who have been here for years, offer many product and customization varieties. Reading through sample packs provided by the supplier is useful as well, and a place where you can learn if there are any customer testimonials or reviews of customers who have previously used it. Lastly, purchase from those resources who can give you awesome customer service and support - If anything goes wrong with the case or an issue occurs related to it then a fast solution can be more valuable than gold.

Plastic Enclosures Uses

From consumer electronics, like smartphones, tablets and gaming consoles to industrial control systems including PLCs,motor drives and power supplies; plastic enclosures cater for a vast scope of devices. And this is reinforced by the fact which they can be used in so many different environments, as ranging from medical devices to HVAC systems and lighting controls (to provide but a few examples of applications for these sensors).

In Summary

Not only are they one of the most versatile, durable and cost-effective solutions around, but also a type that has been embraced for virtually an unlimited number of applications. Most industries regard them as either an option of value or a best alternative for reasons indicated above over conventional cases. For top authenticity and to safely obtain such Plastic Enclosures, make the buy from best-use plastic enclosures suppliers that adhere by essential compliance regulations. Plastic enclosure offers some valuable advantages - protecting your equipment but also helping you to keep the order, and easy access for critical components.