When it comes to guarding your electronics, plastic housing stand alone as a best way for durability in addition safety. These enclosures are significantly easier to hand as they weigh less than your traditional metal enclosures. This Hongfa Shunda outdoor electrical junction box will take you through the advantages and make your product cases out of plastic how these or their utility are helpful for achieving precision results.

You can take plastic enclosures anywhere with you because of its light weight and it would not bulge out space in your purse like if you were to have a thick wallet from the 80s. Overall, the quick usability and assembly of plastic enclosures on to PCBs leads in production savings with respect to time and money. Metal enclosures use more parts and tools than plastic options, making them a bit trickier to assemble where most of plastick cases are assembled with snaps or screws. Moreover, the standard sizes and common types of plastic cases can serve a diverse purpose

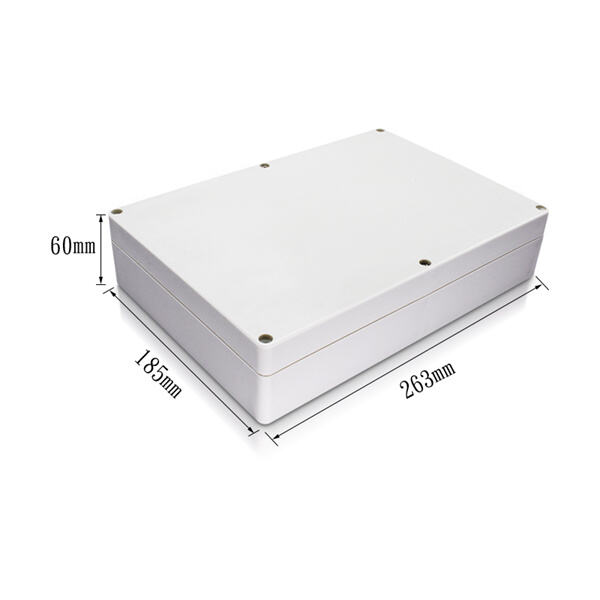

Customizable and Flexible - Designers can further utilize the appeal of plastic enclosures by designing them in ways that other materials cannot, like unusual shapes or sizes with colors matching their branding. Also, Hongfa Shunda waterproof outdoor electrical box enclosures can be molded specific or machined to allow for elements such as buttons, ports and displays essential to the design.

The industry of the plastic enclosure have been in a constant state regeneration, always offering new solutions which would meet the numerous demands in respect to this advanced electronics market. A noteworthy leap has been the use of premium engineering plastics such as polycarbonates and TPU (thermoplastic polyurethane) elastomer TPUs, which deliver higher impact strength along with heat & chemical resistance compared to commodity plastics. Hongfa Shunda outdoor junction box makes the materials not only more durable, but also considerably easier to hold (which is especially useful when we're talking about hand-held devices

A further example are innovative developments that build smart features such as wireless connectivity, sensor or display elements directly into plastic enclosures. How Does this Integration Enhance Overall Usability and Efficiency Apart from the usability of these platforms, making it available for remote monitoring facility increases its efficiency. In addition to that, plastic enclosures can now be developed as water-resistant ones; dust-proofing is no longer an issue and they are also shock-absorbent - which means you would even consider using it in outdoor ventures or industrial sector.

While using plastic enclosures is quite easy, adhering to some basic principles will ensure the best performance. The first step is to choose the correct size, shape and type of plastic enclosure made for your device that fit with factors such as Circuit board space, Component volume ratio and Desired function

Proper assembly matters greatly as well, with the selected plastic enclosure fastened securely together - using snapping- or screwing-methods for these connections and including all necessary holes to access buttons, ports, battery sections (for charging), etc. based on design requirements. When installing your product in the casing, it is highly recommended to conduct comprehensive electrical testing for problems such as short circuits or overheating. In addition, waterproof electrical box is necessary to make sure that enclosure material and design meets all requirements of the device; corresponding safety regulations must also be taken into account concerning your product in specific market.

Our plastic enclosure made up highly skilled engineers, technicians craftsmen years experience expertise metalworking. With eye every detail, guarantee every component meets strictest standards quality precision.

To meet demands customers, we offer complete product lines include aluminium plastic enclosures sheet metal housings. We have CNC precision-machined components, standard products OEM products, many more. Plastic metal cases used diverse industries uses, including construction, electronic equipment medical equipment, many more. We meet your needs, whether need strong, small case USB big, robust case power tool.

Hongfa Shunda put quality first every plastic enclosure, starting conception product, acquisition raw materials, monitoring process along 100% appearance inspection before shipment packaging, making highest effort make sure item purchased client reputable high quality.

We offer tailored solutions meet clients' specific requirements. work closely clients offer solutions beyond expectations, whether manufacturing prototyping. Our plastic enclosure range services allow to take complex projects beginning end.

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. All Rights Reserved - Privacy Policy