Home Business Cold Chain Management Plastic Electronics Enclosures Are Best In Class To Keep Your Machines Safe And Sound

Do you want a reliable way to protect your electronic machines? The solution in this case is as simple that of using plastic electronics enclosures. Specialized cases may have numerous advantages and are popular for many sorts of equipment. We will explain more about why plastic electronics enclosures are a safe and wise choice to use.

Reasons Why you Should Consider a Plastic Electronic Enclosure

PriceThe perhaps most significant appeal in favor of plastic enclosures is their relatively low price, identical to Hongfa Shunda's product server enclosure. Plastics have the advantage of being relatively low-cost to produce, as compared with materials like metal or glass. Furthermore, the enclosures are light hence easy to carry from one point to another. These boxes are durable, so they can withstand poor environmental conditions such as varied temperature and humidity.

Plastic Electronics Enclosures: The materials used by most in the plastic electronics enclosures realm are so advanced, the same as pcb box aluminium enclosure produced by Hongfa Shunda. That includes adding new design elements and finishes to meet the demand for more sophisticated, functional enclosures. Rapidly mainstreaming cutting-edge tech has afforded companies the ability to custom-tailor designs for individual consumers, including uniquely sized products and different color or material options.

The installation of plastic electronics enclosures will help safety in a finer way as it is insulated and non-conductive, minimizing the chances of any electrical system disasters or short circuits. Furthermore, these enclosures are designed to meet standard requirements like NEMA, IP and RoHS regulations thereby meeting global safety norms.

Applications of Plastic Electronics Enclosures are very Diverse

Plastic electronics enclosures are used in a large variety of industries, from oil and gas to military all the way across automotive and healthcare, as well as the Hongfa Shunda's sheet metal enclosure. These provide a low-cost alternative to protect electrical devices from harsh environment, water and dust other extreme environments. The universal enclosures can be used for many applications including robots, sensors and IoT devices.

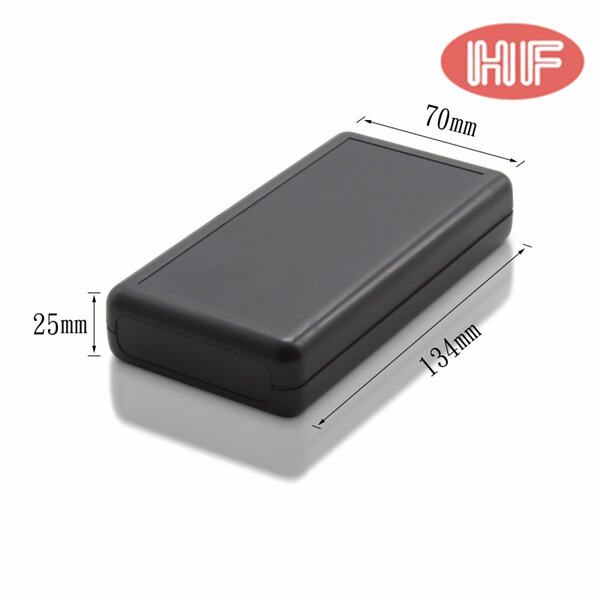

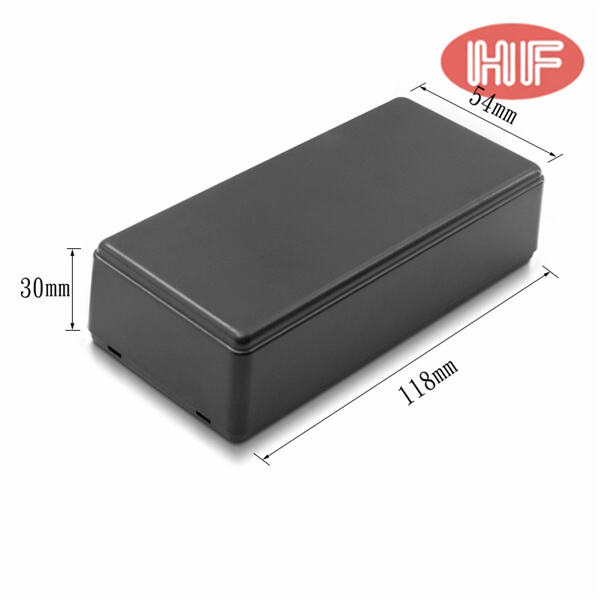

Plastic Electronics Enclosuresare imple and straightforward. The initial step is to choose an enclosure and ensure the size can fit well with your machine, also the aluminium casting enclosure from Hongfa Shunda. Follow the manufacturer's recommendations for installation of your machine properly in an enclosure. After you have located your machine, make sure to either cover or keep an opening where the air bubbles are flowing out plainly so that it also provides a good ventilation of those unwanted fumes.

You need to ensure that you receive high-value in exchange for your investment while choosing plastic electronics enclosures, same with Hongfa Shunda's outdoor enclosure for electronics. Whenever possible, choose a reputable manufacturer who stands behind their products with outstanding customer support. By doing this, you will locate the certifications like UL, CE and ISO confirming that security control measures are strictly followed by the manufacturers.

We tailor solutions plastic electronics enclosure clients' particular requirements. Whether it's prototyping, manufacturing, assembly, work closely clients deliver solutions meet exceed expectations. CNC laser cutting machining, welding sheet metal fabrication provide wide assortment manufacturing capabilities help various industries different applications. broad range services allow manage complex projects conception completion.

manufacturing facilities plastic electronics enclosure cutting-edge technology advanced machinery, enabling make high-quality precision components unmatched precision efficiency. team consists highly experienced engineers, technicians craftsmen who possess years experience expertise metalworking. pay close attention every single detail ensure product exceeds highest quality precise standards.

Hongfa Shunda puts product's top-quality first, beginning design process, purchasing raw materials, observing step process, plastic electronics enclosure inspection appearance before packaging shipping.

complete product line, ranging aluminium enclosures, sheet metal housings CNC precision machined components standard products OEM custom products, meet the various requirements various customers. Metal plastic cases utilized many industries applications including electronic equipment, construction medical equipment. Whether you need small robust durable case your USB big, rugged case power tools We have solution right you.

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. All Rights Reserved - Privacy Policy