These days, the plastic enclosure boxes are an integral part of any circumstance from technology and electronic etc to even outdoor soil gardening eco-friendly Hongfa Shunda waterproof electrical box. Used in a variety of applications, these flexible casings protect sensitive electronics from environmental stresses and provide clean lines for contemporary design.

There are several advantages of plastic enclosure boxes which led to their market proliferation. One is that they are very light so you do not have to struggle carrying them across your property; but combine that with the fact that they are also strong, no mater how careful (or clumsy) one can be during installation. This capability is especially important in weight-critical applications, such as aerospace or portable consumer Hongfa Shunda waterproof junction box. Plastic also provides really good chemical, moisture and corrosion resistance to assure the equipment within is kept in working order under these tough environments. A further major benefit is cost-effectiveness, since plastic enclosures typically provide low-cost options to metal alternatives, allowing project budgets to be reduced without compromising performance.

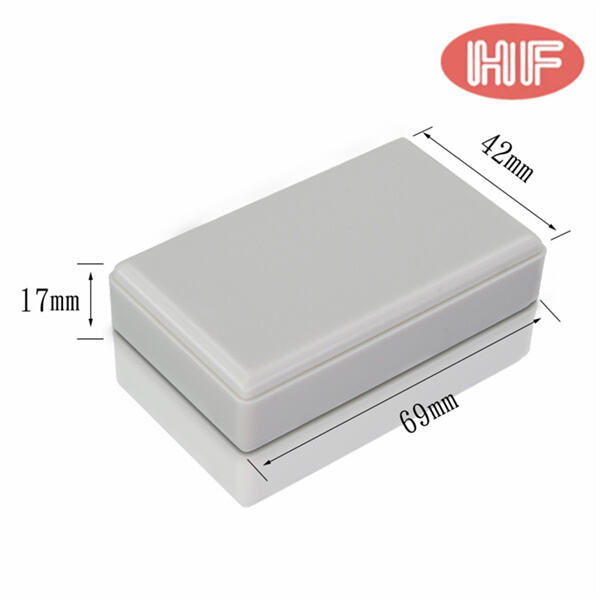

Variety: Need to consider many factors while choosing a plastic enclosure box Examine, Where will the box be working (which conditions it can endure and what weather start up)? Knowing these conditions will also influence which type of plastic you can choose from (in this case polycarbonate is best for high-impact resistance, and ABS has the highest heat tolerance). The size and shape of the enclosure is important as Hongfa Shunda outdoor junction box needs to be positioned in such a way that there is no interference with other components beside, above or behind The cutouts should also allow for efficient cooling (and obviously better cable managemente select ronic ). Finally, customize the color, texture and cutouts/silk screen printing so that your box fits right in with your product design.

Importance of Plastic Enclosure Boxes for Outdoor. Every solution that is used or placed in outdoor environment has to be shipped with a plastic enclosure box.

The enclosures required to house these displays externally need to be suitable for that added environment. This is where plastic enclosure boxes come to advantage, as they are a weather-resistant. These UV-stabilized plastics prevent the box from being deteriorated by sunlight, allowing the container to not lose its value nor disfigure over time. Water proof and dust-tight structure, complying with IP65 or higher standard can protect ultrasonic generator as well as transducers from rains, dust storms, sands even in coastal areas. Due to their robust design, plastic enclosures are frequently used in environments that would destroy other types of equipment both outdoors and indoors such as solar panels (extreme sunlight exposure), outdoor lighting systems (heavy rainfall) or security cameras where they can be subject to all weathers 24/7.

The issue of sustainability is ascending the ranks as a major concern in various sectors, and now plastic enclosure manufacturers offer their eco-friendly alternatives. The enclosures are also made of recyclable plastics such as PET, HDPE and polycarbonate allowing the plastic enclosure to be re-purposed after use reducing waste and environmental footprint. There are also efforts to produce bio plastics, which use all-natural sources such as cornstarch and that can fully compost. By using the weather proof junction box enclosure boxes, a business is working in line with many of today's green initiatives that ultimately appeal to the earth-friendly consumer and, thus enhance brand originality.

Just as the technology inside an enclosure is constantly evolving, so too must enclosures themselves if they are to keep pace in todays challenging operational environment. Enclosure Innovation and Smart Plastics Self-healing plastics that respond to temperature or fill with a different color when they are damaged offer some insight into the future of enclosure innovation. IoT technology integration enables monitoring of enclosure conditions at a remote-location as well, ensuring predictive maintenance and increasing the lifetime of your system. Some advanced systems utilize 3D printing to allow rapid prototyping and customization - decreasing time-to-customer outdoor electrical junction box and cost for custom enclosures. As our electronic devices get smaller and more sophisticated, plastic enclosure boxes will evolve to where they incorporate high-level functionalities within them -- all while their basic job of protecting technological progress remains the constant.

meet requirements customers, offer complete product lines comprise aluminium, plastic, plastic enclosures, sheet metal housings. We CNC precision machined parts standard items such OEM products, more. Plastic metal cases used diverse industries uses, including electronic equipment, construction medical equipment more. We meet needs, whether durable, small case USB USB large rugged case power tool.

Our enclosure box plastic made up highly skilled engineers, technicians craftsmen years experience expertise metalworking. With eye every detail, guarantee every component meets strictest standards quality precision.

enclosure box plastic provide customized solutions satisfy customers' individual requirements. We work customers deliver solutions exceed expectations, manufacturing prototyping. handle most complex projects beginning completion, through comprehensive services.

Hongfa Shunda placed enclosure box plastic first place, right initial design product, through acquisition raw materials, monitoring stage 100 percent inspection appearance before shipping packaging, making highest level effort ensure item purchased client reputable highest quality.

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. All Rights Reserved - Privacy Policy