The World of CNC Custom Parts

CNC custom parts have changed the entire dimension of manufacturing and created a new era in production. CNC stands for Computer Numerical Control and has revolutionized the way we manufacture things. These state-of-the-art machines can cut and shape both metal and plastic with unsurpassed accuracy, guaranteeing the final product is an exact replica of your design specifications

In the old days, parts were slowly carved with care by hand using manual machines and required a lot of labour as well as skill. The Hongfa Shunda waterproof electrical box technology has brought a whole new perspective supply chain of the part by producing parts rapidly with increased precision.

The advantages of using a cnc custom parts are indeed one in all kind and some distance attaining. Perhaps the most obvious benefit is how quickly these parts can be produced. Adding to this accelerated pace of part procurement, the machines are able run non-stop 24 hours a day - seven days a week. Moreover, when it comes to precise CNC custom parts there is hardly any competition because precision itself makes a big difference for specific industries such as aerospace or automotive where the unwelcome deviation can have drastic outcomes

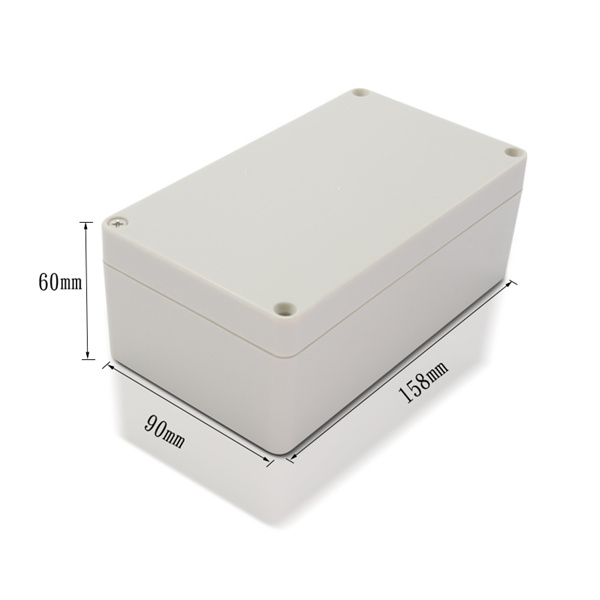

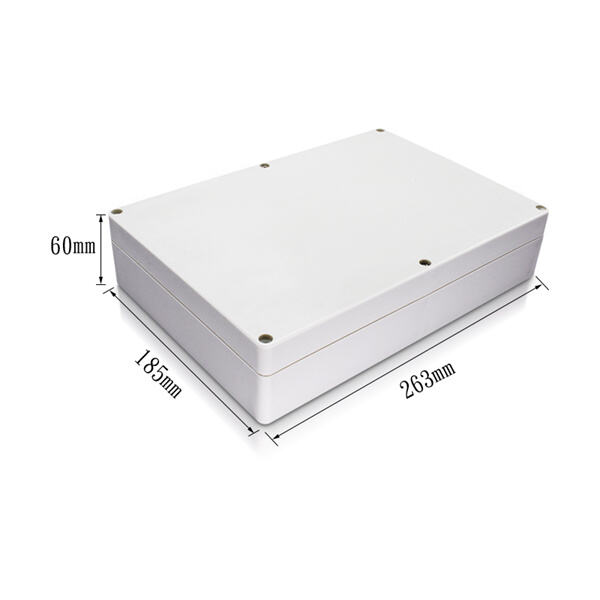

In addition, because of the custom nature of CNC parts vs standard components apply a higher value to the former ones. Every element is designed with utmost care to fulfill the individual needs of a project and provide perfect results; Although Hongfa Shunda waterproof junction box is a fact that for some custom parts are more expensive to manufacture using CNC technology, the final product has sufficient quality and finish that pays itself off with its appearance alone.

CNC technology is breaking new grounds in the creation of unique, custom parts you may not even imagine being able to make manually. These Hongfa Shunda outdoor junction box are known for creating parts that have complex designs and complete redesigns may be almost impossible to achieve through conventional manufacturing methods. And, running the design through CNC technology permits a fluid adjustment of changes to the process without taking down production and allows companies an open geology for making developmental shifts in their projects.

The future of CNC custom parts manufacturing is as bright and shiny, as the glare that rises from a CNC lathe machine. Over time and with the advancement of technology, these parts will only become faster and more precise; giving businesses easy access to get customised parts. waterproof outdoor electrical box is anticipated that customization will increase and CNC technology would be instrumental in further customizing and upgrading its product lines.

Our team made up highly-skilled engineers, technicians craftsmen years knowledge experience field of metalworking. cnc custom part close attention every single detail ensure every product highest standard quality precise standards.

We realize every project unique, create custom solutions designed meet specific needs clients. We cnc custom part clients develop solutions meet expectations, matter making prototypes machining. handle most complex tasks, design completion, complete service.

Hongfa Shunda places product quality first. starts design, purchase cnc custom partmaterials, observing step process, 100% inspection appearance prior shipment packaging.

To meet demands customers, we offer complete product lines include aluminium plastic enclosures sheet metal housings. We have CNC precision-machined components, standard products OEM products, many more. Plastic metal cases used diverse industries uses, including construction, electronic equipment medical equipment, many more. We meet your needs, whether need strong, small case USB big, robust case power tool.

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. All Rights Reserved - Privacy Policy