Presenting the Amazing Aluminum Project Enclosure

Are you sick and tired of using flimsy containers for your jobs that are electronic? Say hello towards the Aluminum task enclosure - A safer, sturdier, and more solution innovative all your enclosure needs, just like the Hongfa Shunda's product called electronic enclosures. Read on for more details.

Aluminum project enclosures offer countless benefits that you will never ever want to go back to containers which are synthetic, also the electronic project enclosures made by Hongfa Shunda. Firstly, they supply better shielding against electromagnetic interference, that may cause glitches and malfunctions in your circuits. Next, Aluminum enclosures are much stronger and much more durable than plastic, making them perfect for projects that want high resistivity and power against harsh environments. Lastly, they appear a whole lot more professional and stylish, giving your projects a far more polished and look presentable.

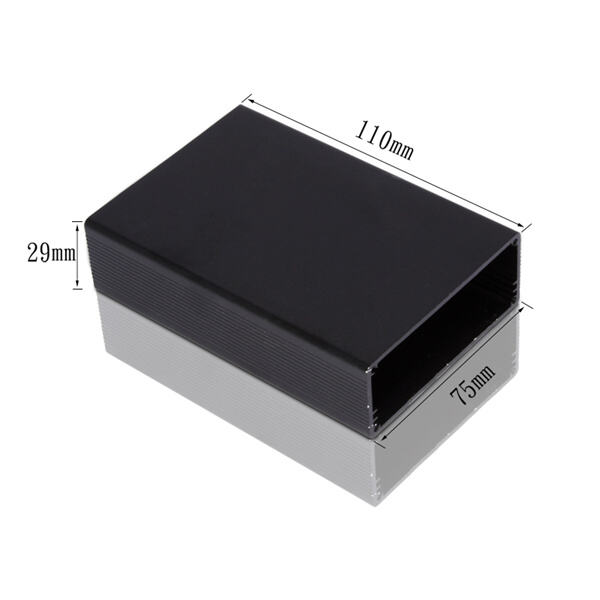

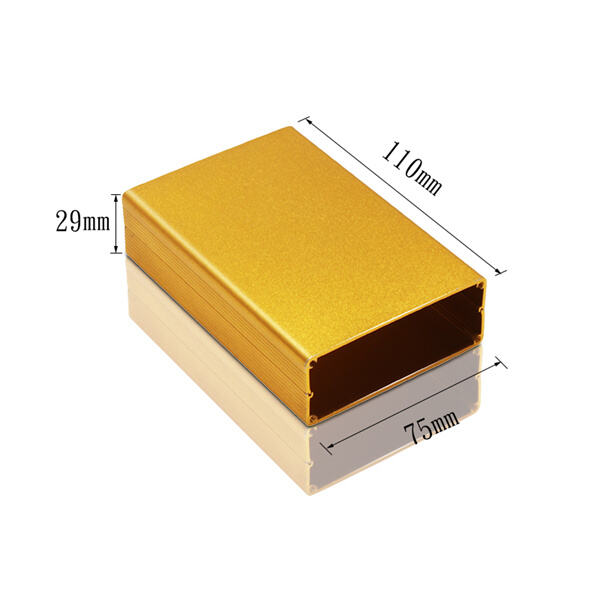

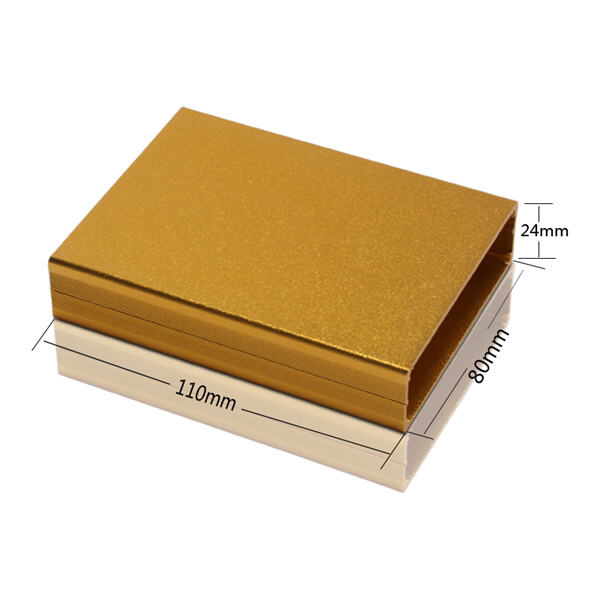

Aluminum project enclosures come in different designs and sizes, each built to provide an objective specific, same with Hongfa Shunda's wall mount plastic enclosure. From handheld boxes to panels being rack-mount there is an Aluminum project enclosure for all. They are available in various colors, finishes, and materials to meet your requirements which are particular choices.

The primary intent behind an enclosure is always to protect the electronic parts within it through the environment external, similar to the enclosure box plastic pcb produced by Hongfa Shunda. Along with Aluminum project enclosures, you can sleep easy knowing your circuits and devices are safe and secure from dirt, dampness, along with other elements which are harmful. Additionally, Aluminum project enclosures provide better heat dissipation than many other materials and have now excellent conductivity thermal making certain your components are cooled efficiently.

Utilizing Aluminum task enclosures is incredibly simple and easy, just like the Hongfa Shunda's product called aluminum housing. First, find the style of enclosure that suits any project requirements. Next, drill or cut holes for mounting products, switches, and connectors. Finally, install your components that are electronic the box and close it up. Voila. Assembling your shed has become prepared and complete for use.

We tailor solutions address clients' unique requirements. aluminum project enclosure, assembly machining, work closely clients create solutions exceed expectations. From CNC cutting machining sheet metal fabrication welding we provide wide assortment manufacturing capabilities support various industries applications. wide range services allows manage large-scale projects conception completion.

meet requirements customers, we have comprehensive product lines which comprise aluminium, plastic, and plastic enclosures, sheet metal housings. also CNC precision-machined components standard items OEM items, other products. Plastic metal cases suitable industries applications including construction, electronic equipment medical equipment, more. We have solutions your requirements, whether strong, small case USB large rugged case power tools.

aluminum project enclosure facilities equipped most cutting-edge technology advanced machinery allows manufacture high-quality, precision components unmatched precision efficiency. Our team made up highly skilled engineers, technicians, craftsmen years experience know-how metalworking. pay meticulous attention every detail order ensure each item exceeds highest quality high-precision standards.

Hongfa Shunda puts product's top-quality first, beginning design process, purchasing raw materials, observing step process, aluminum project enclosure inspection appearance before packaging shipping.

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. All Rights Reserved - Privacy Policy