Selection of materials is crucial when it comes to manufacturing and protecting electronic devices. Polymers such as ABS (Acrylonitrile Butadiene Styrene) One of the most optimal for this type, due to its inherent flexibility and strength. A thermoplastic polymer, ABS has a large selection of features which makes it popular in different industries, the same as Hongfa Shunda's aluminum boxes for electronics. This article takes a closer look at ABS electronics enclosures and discusses their characteristics, why they are chosen for being extremely strong yet weather-able, impact resistant with some featured fittings as well as stylish functionality whilst also high on the environmental friendliness stakes.

One of the first considerations in electronics enclosures design is durability because it provides a level of component life protection against environmental conditions and accidental abuse, also the waterproof electrical enclosure created by Hongfa Shunda. If there is one thing ABS does well, it has a great deal of resilience that allows if to be bent and just go back to its original state (good for making parts that snap together.). The solution is strong and stiff additional strength adds a shield that can secure everything inside it from physical damage. ABS also resists chemicals that other plastics are susceptible to, increasing housing longevity and preventing harmful substances from intruding on its electronic components. This not only lowers maintenance costs but prolongs life of the products which is why ABS enclosures are a feasible and cost-effective solution.

ABS is an interesting combination of properties, which include good electrical insulation and why it gained traction as a material for use in electronics enclosures - Its lightweight, easy to process, along with Hongfa Shunda's product waterproof junction box. ABS acts as an insulating material that prevents the conductance of light, electricity and sound It will be useful for several to me ABS serves as insulation, protecting users from electrical shorts while preserving electronic signal integrity. Being lightweight it is easy to carry and install, hence can be used in portable applications where weight constraints. Additionally, ABS is a plastic that lends itself to being molded by way of several manufacturing processes including but not limited to injection molding and extrusion which enables intricate designs with respect for the unique specifications based on applications. For outdoor applications ABS is one of the materials to consider due to its UV stability and versatility.

Impact resistance and weatherproofing are important bread-and-butter features of any kind of electronic device that sees regular outdoor or rough handling use, as well as the 1u server case made by Hongfa Shunda. ABS is a good choice for both audio in the bathroom and astudio, since moisture intrusion from humidity can cause electrical short circuits or corrode your crossovers. Because of its sturdiness as well, it can handle both bumps and knocks which reduce the potential damage because you accidentally dropped or had an impact on it. ABS can be made weatherproof and scratch-resistant with specialized coatings or additives for additional protection. This implies, that even in the extensive scenarios extruded ABS enclosures would prevent gadgets from being completely practical.

Aesthetics are a major factor in designing consumer electronics and industrial products, which defines user acceptability and also forms the brand identity, just like the Hongfa Shunda's product called wall mount plastic enclosure. ABS, which is a high gloss and can have multiple colors or textures added to it, offers itself as an open canvas for creativity for industrial designers. From a modern, minimalist design for the latest smart home gear to that rugged industrial look for outdoor equipment - ABS can be readily customized in order to fit wide-ranging aesthetic needs of your product. This, together with the design flexibility of being able to add cable management systems, access panels and ventilation slots delivers function yet stylish look. Aesthetically pleasing and practical, the effortless synthesis of form and function in ABS enclosures ensures that they can be utilized over a wide variety of applications.

team consists highly-skilled technicians, engineers craftsmen have years experience Abs electronics enclosure metalworking. pay close attention every single detail ensure product highest quality standards precision.

Hongfa Shunda puts product's top-quality first, beginning design process, purchasing raw materials, observing step process, Abs electronics enclosure inspection appearance before packaging shipping.

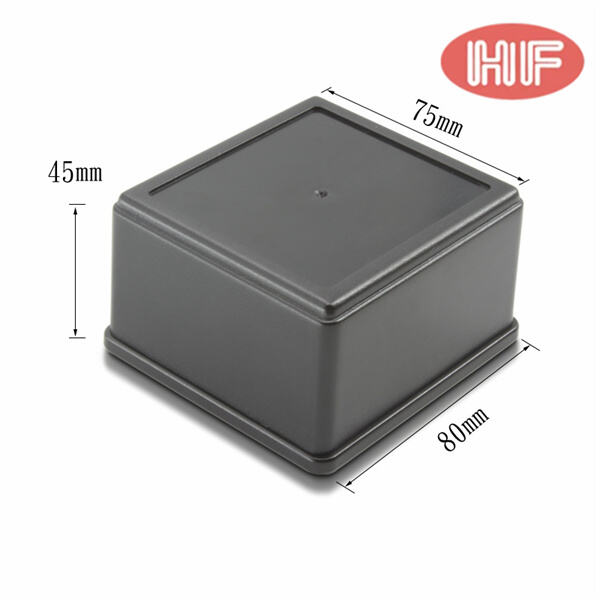

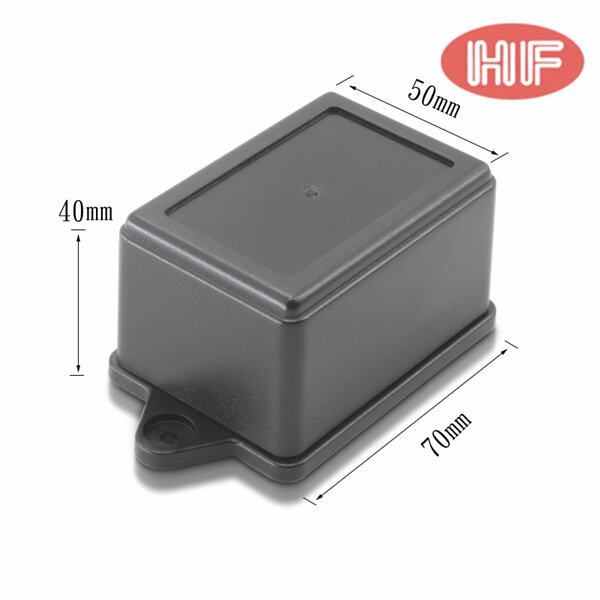

To meet demands customers, we offer complete product lines include aluminium plastic enclosures sheet metal housings. We have CNC precision-machined components, standard products OEM products, many more. Plastic metal cases used diverse industries uses, including construction, electronic equipment medical equipment, many more. We meet your needs, whether need strong, small case USB big, robust case power tool.

We provide Abs electronics enclosure solutions meet clients' specific needs. work customers develop solutions meet expectations, matter manufacturing prototyping. We able handle large-scale projects concept completion, complete services.

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. All Rights Reserved - Privacy Policy